Conversal

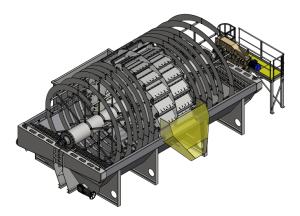

Successful test of Metso slurry pump XM500

Successful ISO test of an impressive Metso slurry pump type XM500 at the Metso pump factory in Sala, Sweden. XM stands for extra heavy duty slurry pump. Now that the pump has passed the test successfully we can complete the assembly and start packing ready for shipment towards the customer.

This pump, together with some additional Metso slurry pumps was sold by Lutze Process Belux BV. For more info, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Longer service life guaranteed: Lutze and Nomig protect the pump housing against wear and chemical attack

Lutze and Nomig: Sustainable solutions for long-term protection

Three years ago, Lutze was called in by a Dutch customer to solve a complex challenge. A cast iron pump housing of a macerator, which after 1.5 years of use was suffering from severe wear and corrosion due to low pH values, needed better protection to extend its lifespan.

We then decided to have the pump housing fitted with a SiC casting polymer by Nomig. This intervention would certainly make the pump housing more resistant to the harsh conditions in which it operated.

Now three years later, the grinding ring urgently needed to be replaced and this gave us the opportunity to take another look at the pump housing from the inside. Thanks to the durable protective layer applied at the time, the pump housing showed only minimal wear and very little chemical corrosion this time. The pump housing that has now been in use for 3 years looks much better than the untreated pump housing after 1.5 years!

The grinding ring has now been replaced and the pump housing has been given a good refresh. The pump (the pump housing) can now certainly last for years to come.

This successful collaboration shows how important it is to invest in high-quality protection solutions. Thanks to Lutze's expertise and Nomig's innovative products, the customer is assured of a longer lifespan for his pump. Due to the SiC casting polymer treatment of the pump housing, the customer is assured that their maintenance costs can be significantly reduced and the lifespan of their pump is extended.

All the advantages of this solution in a row:

- Extended lifespan of critical components

- Reduced wear and chemical attack

- Less maintenance and lower costs

Would you like to know more about how we can protect your equipment and extend its lifespan? Then contact us for free advice!

Commissioning new Sandvik CH430 crusher with associated MCR platform

Successful commissioning of a new Sandvik CH430 crusher with associated MCR platform at a customer active in building material recycling and will be used for crushing dry concrete material. Machine was sold and put into operation by Lutze Process Netherlands BV.

Delivery and installation of a new Stichweh wash and dewatering bucket wheel type ES 5022 BB to handle a sand slurry up to maximum 350m³/h of sand on a floating sand extraction installation.

Lutze Process supplies a new suction dredge bucket wheel type E 6522 H from our partner Stichweh for a capacity sand & gravel up to 700T/h.

New log washer type DSW200/2100/6000

Supply and installation of a new log washer type DSW200/2100/6000 with a capacity up to 200T/h manufactured by our partner SMT-Stichweh.

Lutze Process receives the order for the supply of a new Stichweh bucket wheel

Lutze Process receives the order for the supply of a new Stichweh bucket wheel type ES 5022 BL100 to be installed onto a floating sand processing plant.

Special demands? Lutze Process Delivers!!

Special delivery of a special pump!

Metso:Outotec offers the possibility to extend the submersible depth of the Vertical Sump (VS) pumps. The normal maximum depth is 1800 mm but in this case and due to the extended frame construction it is 2500 mm. We also fitted a 700 mm stainless steel suction tube.

If you have special demands for your slurry pumps don't hesitate to contact Lutze Process, your official distributor for Metso:Outotec slurry pumps and parts in the Benelux --> This email address is being protected from spambots. You need JavaScript enabled to view it. or www.lutze-process.com